The package comprised of:

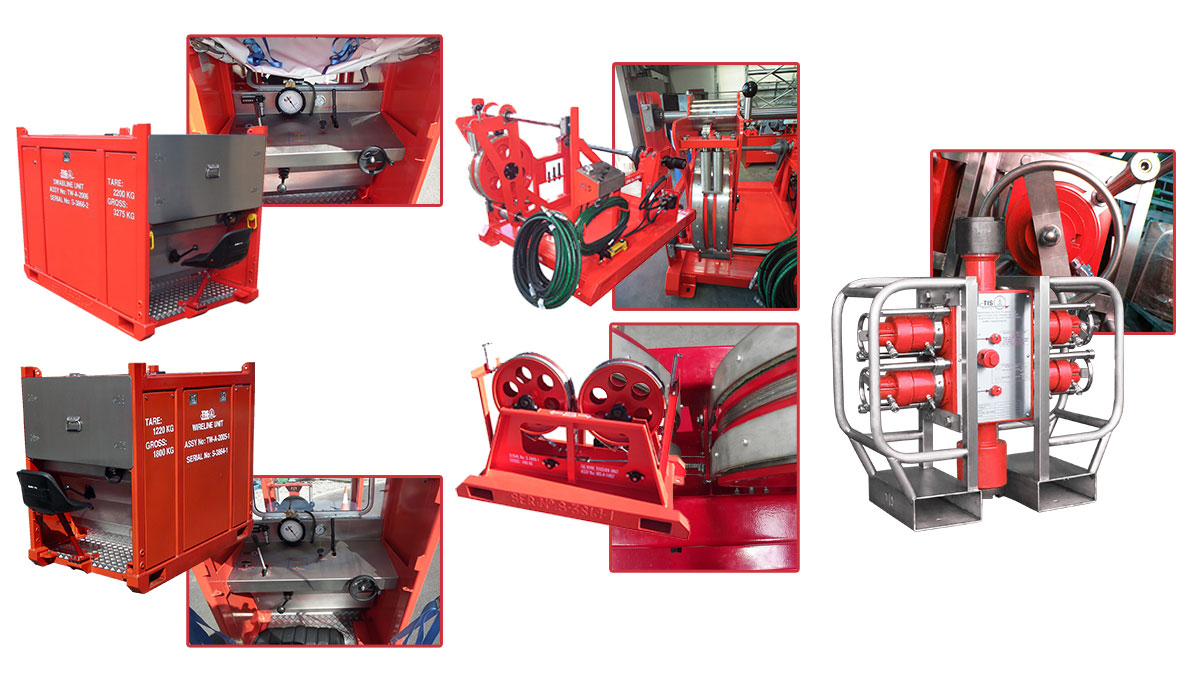

2x Single Drum Slickline Units

2x Single Drum Swabline Units

2x Wireline Spooling Units

2x Wireline Tensioner Units

4x Diesel Powerpacks

2x Electric Powerpacks

2x Pressure Control Equipment Packages

- 2x 4” Dual ‘Apollo’ Wireline Valves

- 2x Grease Injection Heads c/w Strippers

- 2x Elite Toolcatchers

- 2x Blank/Lift Caps

- 2x Test Caps

- 16x 8ft Lubricators

- 4x Crossovers

TIS Wireline Units are designed for controlled deployment and recovery of slickline, braided line and electric line from an open console or fully containerised unit, during well intervention operations. TIS Powerpacks can be designed to any client specification with our field proven designs thriving in harsh environments, and adaptable to any operational requirement needed.

The Slickline, Swabline, and Diesel Powerpack Units in this package were built and certified in compliance with DNV-ST-E271, while the Wireline Spoolers, Tensioners and Electric Powerpacks were supplied for workshop use only.

The Swabline Units (TW-A-2006) were designed to accommodate 26,000ft of 7/32” with a descent control function for logging intervention operations. For easy maneuverability on helidecks platforms, these units were supplied with hydraulic jacking castors which employ a simple Enerpac handpump to raise it onto the castors with limited effort.

The Slickline Units (TW-A-2005-1) was designed to accommodate a range of slicklines – 39.000ft of 0.092″, 28,000ft of 0.108″, or 21,000ft of 0.125″ – for standard slickline intervention operations. Manufactured to be as lightweight and compact as possibly, each wireline unit weighs 1,600kgs with a full drum of the heaviest wire it can hold. A drum changeout kit allows for installation of drums in field, meaning the equipment can be transported in multiple lifts weighing less than 1,000kg each.

The Wireline Spooling Units and Tensioner Units (WS-A-1001 and WS-A-1002) were designed for spooling braided wire onto the swabline units, ensuring the wire is kept under consistent tension to prevent kinks and spaghettifying in operation. The Deisel and Electric Powerpacks (PM-A-1001 and PM-A-3002) were designed to provide the necessary power required for the wireline units and the spooling units respectively.

The 4” Dual ‘Apollo’ Wireline Valves were specifically designed for maximum reliability, flexibility and simplicity of use, while carrying out routine intervention work. The compact design is suited for offshore operations where the valve has to be lowered onto the xmas tree through a restricted hatch space. The WLVs were also supplied with Grease Injection Heads c/w Strippers, Elite Toolcatchers, Blank/Lift Caps, Test Caps, 8ft Lubricators, and Crossovers.

As a leading provider in the design, manufacture, refurbishment and rental of well intervention equipment, TIS have an extensive library of existing designs to offer or use as a base to develop a bespoke solution.

We have a comprehensive track record of delivering the highest quality well intervention equipment on the market including Wireline Units, Wireline Masts, Wireline PCE, Pumps & Panels, and a range of bespoke equipment for our client’s unique intervention technologies.