Since original manufacture, TIS has supported with annual service, major service, pre and post mobilization service, as well as continuous spares inventory. Each package was comprised of the following equipment:

1x 5-1/8” Dual ‘Apollo’ Wireline Valve c/w Protection Frame

1x Grease Injection Head c/w Stripper

2x Hydraulic Stuffing Box c/w Top Sheave

1x 5-1/8” In-situ Test Sub

1x 5-1/8” Pump-in Sub

1x Test/Lift Cap

1x Blank/Lift Cap

6x 8ft Lubricators

1x Wellhead Control Panel

1x 10K Grease Injection Unit

1x PCE Transportation Frame

TIS Pressure Control Equipment is designed to provide a safety barrier while deploying slickline or braided cable into a wellbore for a range of standard well intervention operations. All equipment in this package was built and certified in compliance with API-6A and SI-913 standards.

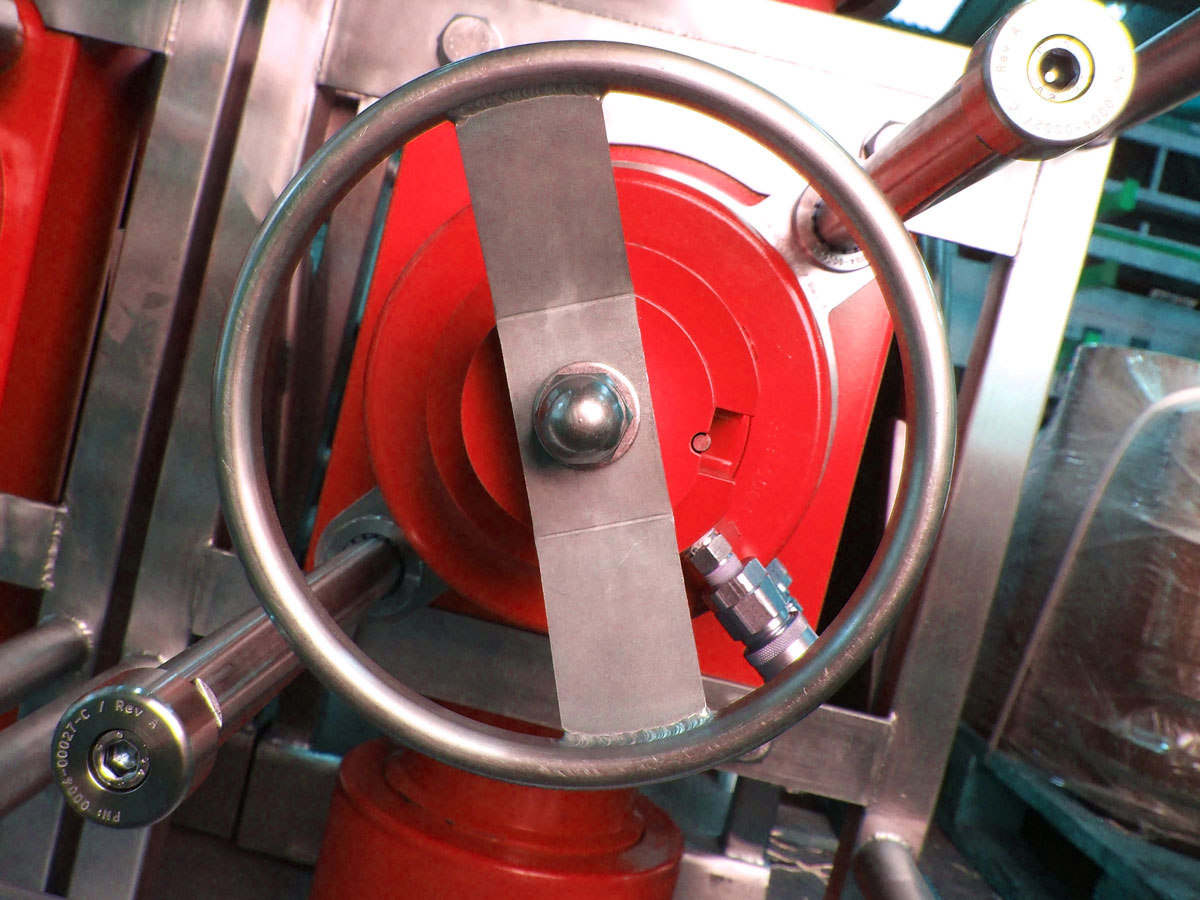

The 5-1/8” Dual ‘Apollo’ Wireline Valves were specifically designed for maximum reliability, flexibility and simplicity of use, while carrying out routine intervention work. The compact design is suited for offshore operations where the valve has to be lowered onto the xmas tree through a restricted hatch space.

The Grease Injection Heads and Hydraulic Stuffing Boxes were designed to facilitate a seal and retain well pressure around moving and stationary braided line and slickline respectively. An operator friendly lightweight construction makes them especially good for man handling and they have been specifically designed to increase the field service life of the wire.

The In-Situ Test Subs were designed to significantly reduce operating costs by removing the need to pressure test before every wireline run. The Pump-in Tees were designed to facilitate a sizeable fluid flow entry path into the surface pressure control equipment during well stimulation or hydrostatic testing operations.

The Test/Lift and Blank Lift Caps were designed to lift heavy items of surface pressure control equipment in a safe and efficient manner. The Lubricators were designed as pressure retaining cylinders used during well intervention operations for tool string deployment.

The 10K Grease Injection Units (CU-G-1002-3) supplied with this order were designed to provide dual supplies of grease to both the greasehead and wireline valve, utilising two independent air hydro grease pumps. A stainless steel mainframe houses a 290L grease reservoir, as well as a smaller 2L reservoir to feed independent line wiper and pack-off function via a hand pump.

The 10K Wellhead Control Panels (CU-W-1020) were designed to control the xmas tree functions and surface pressure control equipment during well intervention operations. The two independent hydraulic control systems have a maximum working pressure of 10,000psi (tree) and 3,000psi (surface PCE) respectively, with fluid delivered to each system under pressure via independent pneumatic pumps (c/w back up hand pumps) and fluid reservoirs. The tree controls include Wing Valve (WV), Master Valve (MV) and a Sub Surface Safety Valve (SSSV), while the surface PCE controls include triple WLV rams, tool catcher and stuffing box. The units also incorporates a local and remote two stage time delayed Emergency Shutdown System (ESD).

The PCE Transportation Frames were designed to provide a DNV-ST-E271 certified skid to transport and house the above pressure control packages.