The equipment comprised of:

6x 3K 4” Quad WLV Control Panels

3x 3K 9” Dual WLV Control Panels

4x 3K 9” Shear-Seal Valve Control Panels

4x 10K Wellhead Control Panels

6x 10K Grease Injection Units

6x 10K Pressure Test Pump Units

5x 10K Hand Portable Chemical Injection Units

1x Vent Skid Hosereel Unit

TIS Wireline Valve Control Units are designed to control wireline valves and other surface pressure control equipment during well intervention operations. TIS Wellhead Control Panels are designed to control the xmas tree functions and surface pressure control equipment during well intervention operations. TIS Grease Injection Units are designed to introduce grease into a lubricator stack, typically for braided line applications, during well intervention operations. TIS Pressure Test Pumps are designed as a safe and reliable facility for pressure testing pressure control equipment during well intervention operations. TIS Chemical Injection Units are designed to introduce various chemicals into the well for cleaning blocked perforations, reducing corrosion, improving flow-assurance, and several other critical applications. All equipment in this package was built and certified in compliance with DNV-ST-E271 and CE ATEX Zone 2.

The 3K 4” Quad WLV Control Panels (CU-B-1005) were designed for control of a 4” quad wireline valve, tool trap, tool catcher, stuffing box, and cable cutter. Control fluid was delivered to the hydraulic system under pressure via twin pneumatic pumps (c/w back up hand pumps for WLV functions) and a 95L fluid reservoir. Four 37L accumulators provide a stored volume at 5,000psi to assist with the WLV functions, with three accumulators designed to assist the top three WLV rams, and one dedicated to the bottom shear seal rams. The unit also incorporated a local and remote operated Emergency Shutdown System (ESD). All functions were connected via 100ft hoses stored on wet centre hose reels with hand wind deployment and recovery.

The 3K 9” Dual WLV Control Panels (CU-B-1007) were designed for control of a 9” dual wireline valve only, with control fluid delivered to the hydraulic system under pressure via a single pneumatic pump (c/w back up hand pump) and a 150L fluid reservoir. Six 54L accumulators provide a stored volume at 5,000psi to assist to assist with the WLV functions. The unit also incorporated a local and remote operated Emergency Shutdown System (ESD). All functions were connected via 100ft hoses stored on wet centre hose reels, with the WLV reels fitted with pneumatic spooling motors to aid in deployment and recovery, while the ESD reel was hand wound.

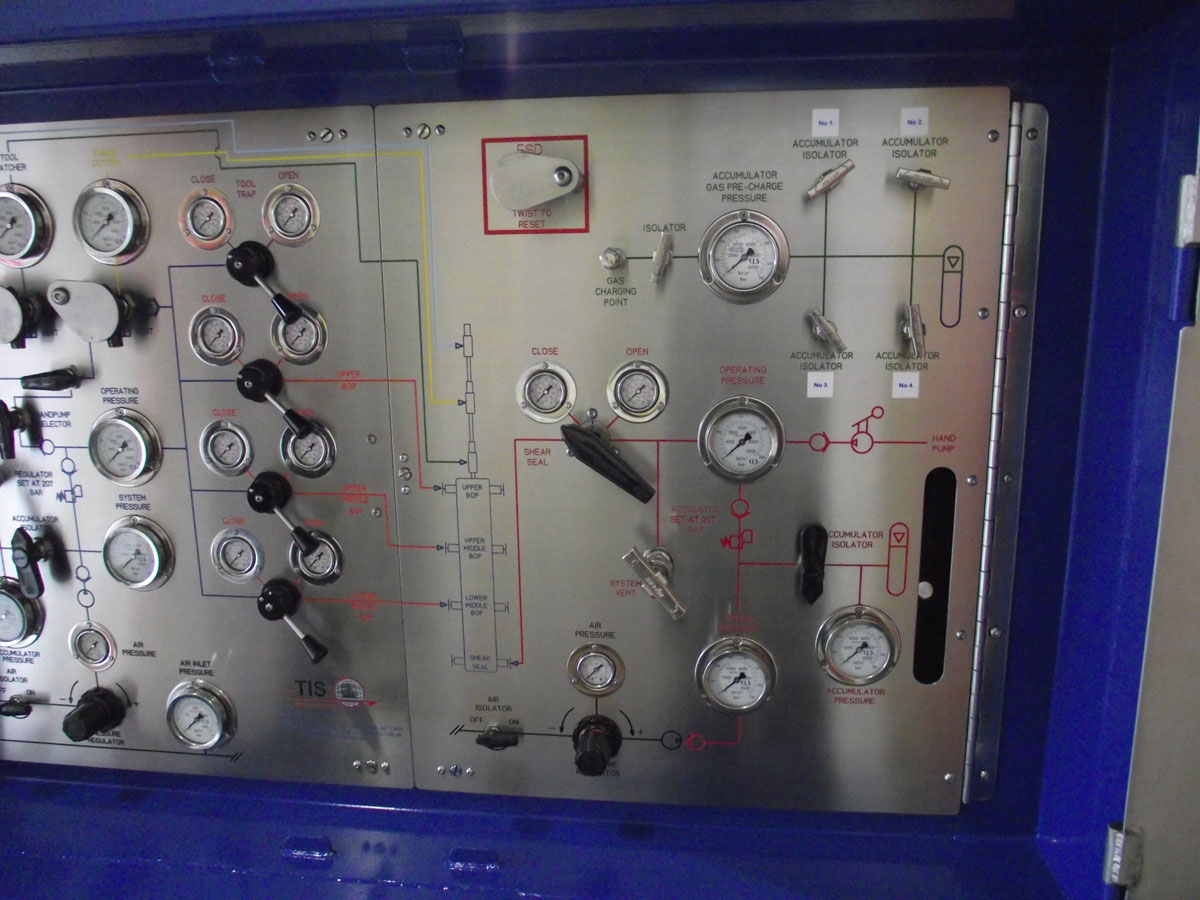

The 3K 9” Shear-Seal Valve Control Panels (CU-B-1006) were designed for independent and dedicated control of a 9” shear-seal valve only, with control fluid delivered to the hydraulic system under pressure via a single pneumatic pump (c/w back up hand pump) and a 70L fluid reservoir. Four 37L accumulators provide a stored volume at 5,000psi to assist with the shear-seal valve function. The unit also incorporated a local and remote operated Emergency Shutdown System (ESD). All functions were connected via 100ft hoses stored on wet centre hose reels, with the WLV reels fitted with pneumatic spooling motors to aid in deployment and recovery, while the ESD reel was hand wound.

The 10K Wellhead Control Panels (CU-W-1028) were designed to control the xmas tree functions and a hydraulic jack function during well intervention operations. Control fluid was delivered to the hydraulic system under pressure via a pneumatic pump (c/w back up hand pumps for the SCSSV) and a 52L fluid reservoir. The tree controls include a Hydraulic Master Valve (HMV), two Hydraulic Wing Valves (HWV) and a Surface-Controlled Subsurface Safety Valve (SCSSV), while the hydraulic jack controls were fed from the same pump. The unit also incorporated a local and remote operated two stage time delayed Emergency Shutdown System (ESD).

The 10K Grease Injection Units (CU-G-1004-1) supplied with this order were designed to provide triple supplies of grease, two to the greasehead and one to the wireline valve, utilising three independent air hydro grease pumps. A stainless steel mainframe houses a 450L grease reservoir, as well as a smaller 2L reservoir to feed independent line wiper and pack-off functions via a hand pump.

The 10K Pressure Test Pump Units (CU-T-1008-1) were designed to pressure test up to 10,000psi from a self contained skid with 1000L reservoir, 100ft hose and integrated chart recorder. Two pneumatic pumps – low pressure and high volume, and high pressure and low volume – assist in filling a void quickly and to the correct pressure to perform and chart a pressure test.

The 10K Hand Portable Chemical Injection Units (CU-T-1007) were designed to pump chemicals, oils, or water based fluids at 10,000psi from a lightweight and compact hand portable frame. A single pneumatic pump, a 10L reservoir, as well as instrumentation controls are housed in a unit weighing less than 35kg.

The Vent Skid Hosereel Unit (HR-A-9009) was designed to accommodate a single 50ft hose with a t-piece in the end, which was hand wound from the reel, and used as an overboard vent line for pressure.

As a leading provider in the design, manufacture, refurbishment and rental of well intervention equipment, TIS have an extensive library of existing designs to offer or use as a base to develop a bespoke solution.

We have a comprehensive track record of delivering the highest quality well intervention equipment on the market including Wireline Units, Wireline Masts, Wireline PCE, Pumps & Panels, and a range of bespoke equipment for our client’s unique intervention technologies.