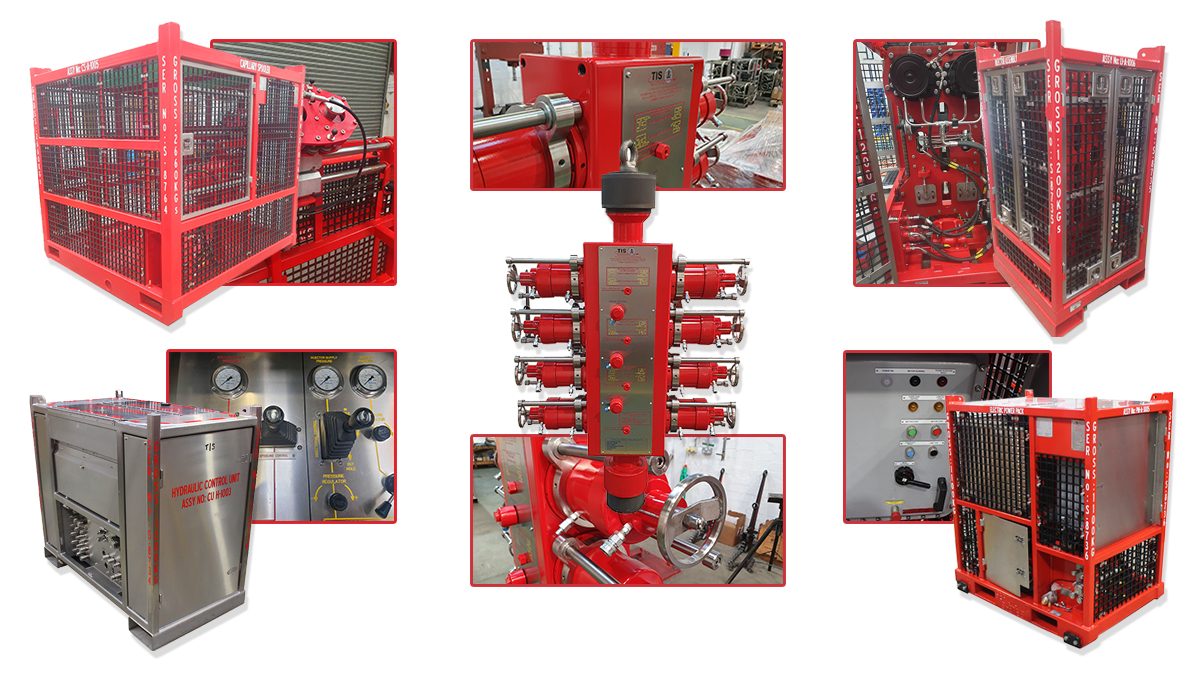

Our team of skilled engineers and technicians provided design, assembly and test of the following equipment:

Hydraulic Control Unit

Capillary Spooler Unit

Injector Unit

Electric Powerpack

Pressure Control Equipment

- 4” Quad ‘Apollo’ Wireline Valve

- Special Snubbing Head

- Test Lift Cap

- Test Mount Stump

TIS Capillary Systems are designed to deploy and recover capillary strings for well intervention by the delivery of chemicals to treat scale, paraffin, corrosion, salting, and other issues. All equipment in this package was built and certified in compliance with DNV-ST-E271 and CE ATEX Zone 2.

The Hydraulic Control Unit (CU-H-1003) is designed to provide control functionality for the Spooler Unit, Injector Unit and Quad Wireline Valve. The unit offers a portable control station which houses the required controls instrumentation, coloured engraved control panel, and accumulators for the wireline valve.

The Capillary Spooler Unit (CS-A-1005) was designed to accommodate drums of up to 66” diameter, for deployment and recover of ¼” or 3/8” OD capillary. A level wind sub-assembly provides controlled spooling to the drum, a counter head measures the length as it spools, while counter balancing hydraulic system provides constant back tension against the accompanying injector unit.

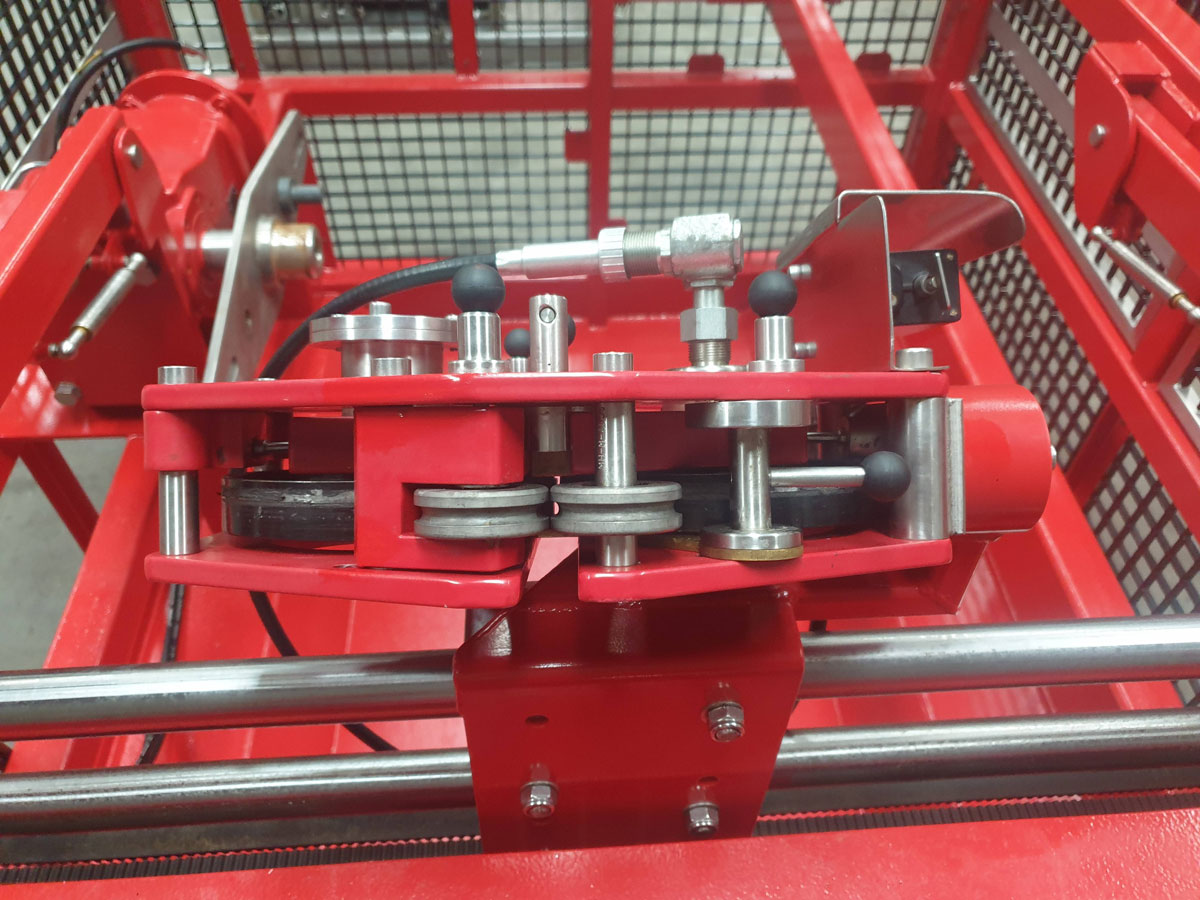

The Injector Unit (IJ-A-1006) was designed to provide controlled deployment and retrieval of ¼” or 3/8” OD capillary strings into the wellbore via the appropriate pressure control equipment. Two hydraulic motors provide continuous drive to a set of chains that grip the capillary to inject or retrieve it, while a top sheave sub-assembly guides the string into the chains.

The Electric Powerpack (PM-A-3005) was designed to accept a utility interface 220V AC (±10%), 3-phase, 60 Hz supply to provide the necessary power required for the above equipment that comprises the capillary package.

The 4” Quad ‘Apollo’ Wireline Valve was specifically designed for maximum reliability, flexibility and simplicity of use, while carrying out routine intervention work. The compact design is suited for offshore operations where the valve has to be lowered onto the xmas tree through a restricted hatch space. This WLV was also supplied with a Test Mount Stump, Lifting Cap Assembly, and a Special Snubbing Head dressed to suit 3/8” tubing.