Our team of skilled engineers and technicians provided design, assembly and test of the following equipment:

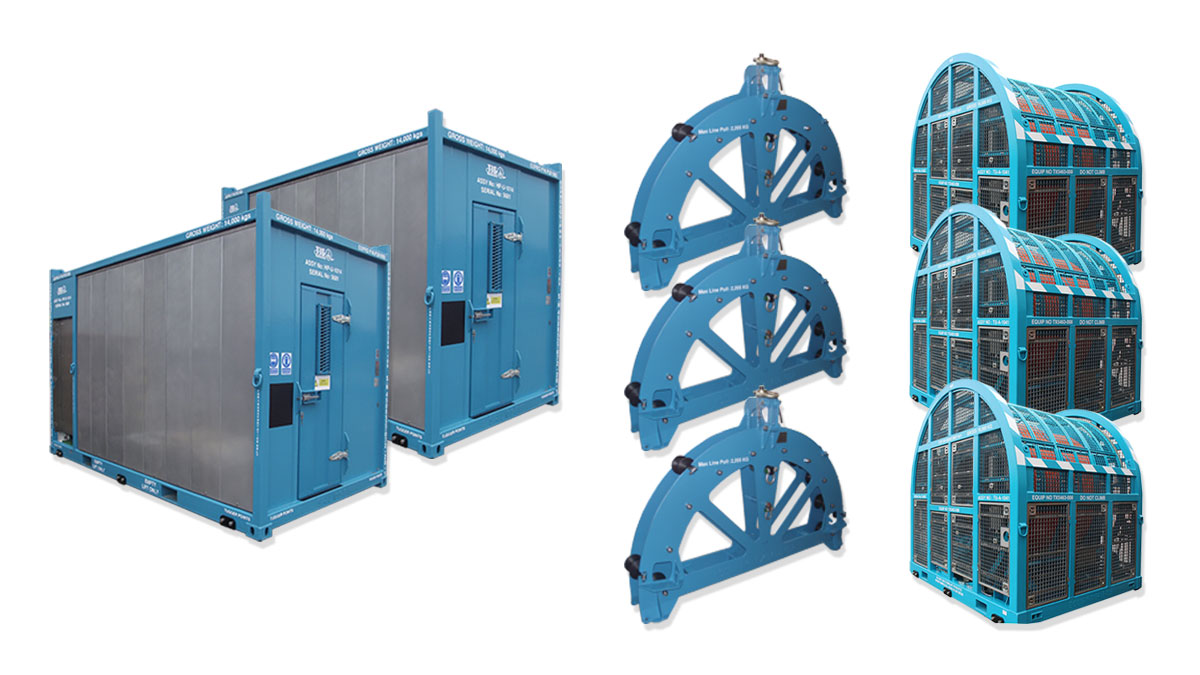

2x PLC Controlled HPU

3x Umbilical Reeler

3x Umbilical Arch Sheave

TIS Manufacturing completed the delivery a Topside Controls Package for a UK service company in 2014, with the equipment bound for development works on the Shah Deniz fields, located in the South Caspian Sea offshore Azerbaijan. Our team of skilled engineers and technicians provided design, assembly and test of the following equipment.

TIS Subsea HPUs are designed to control and monitor subsea trees and associated subsea equipment during well intervention operations, and are typically accompanied by an Umbilical Reeler as part of complete Subsea Landing String (SLS) or Intervention Workover Control Systems (IWOCS). TIS Umbilical Reelers are designed to deploy and recover any length and diameter of umbilical product, with suitable controls to facilitate multiple hydraulic, chemical, electrical and fibre optic power and signal cores.

This topside controls package was used for the client’s electro-hydraulic landing string, typically deployed as part of a system for subsea exploration and appraisal operations. The PLC Controlled HPU was built and certified in compliance with DNV-ST-E271 and CE ATEX Zone 2, while the reeler was built and certified in compliance with DNV-ST-E273 and CE ATEX Zone 1.

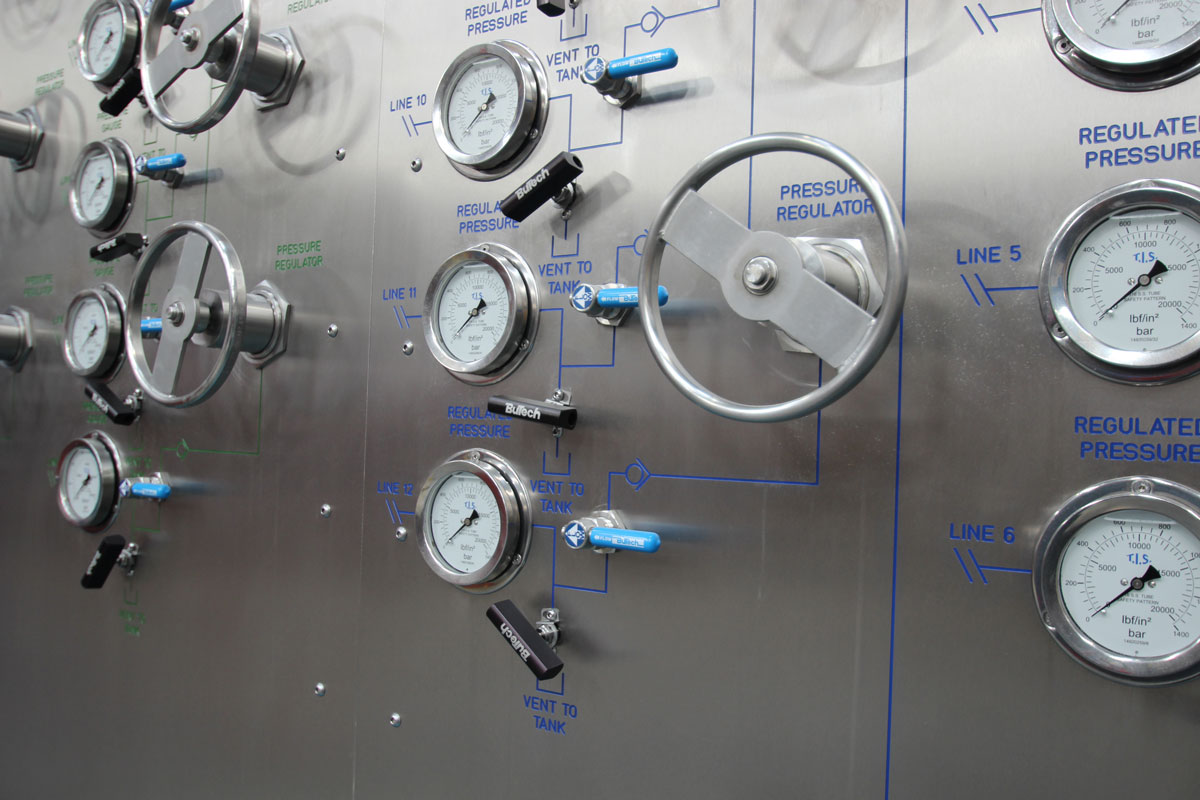

The Hydraulic Power Units (HP-U-1014) were built to client specification to provide a 15,000psi supply to 24 subsea lines, and to be controlled via a programable logic controller (PLC). Control fluid was delivered from one 700L supply and two 300L return reservoirs to the high pressure hydraulic circuit via three air hydro pumps, which provided the required flow at pressure with built in redundancy. Four high pressure 50L piston type accumulators were located in a dedicated section on the outside edge of the HPU while remaining within the unit’s envelope, for the purpose of eliminating operator exposure to risks of stored gas at pressure. The PLC was programmed with the client’s proprietary software and designed to be powered by 110-240V/1PH 50-60Hz supply which was connected via an uninterrupted power supply (UPS) at source.

The Umbilical Reelers (TU-A-1041) were purpose built to suit the client specified umbilical’s cores comprised of nine hydraulic lines, two chemical line, two power cables (each with 10 conductors), and two data cables (each with four conductors). A traverse spooling head sub-assembly was designed specifically to suit the umbilical OD, with two stainless steel endless screws synchronising the distance the spooling head travels per rotation of the reel to provide perfect even wraps to the drum. The spooling system rotates around the top half of the drum to provide a 180⁰ range of horizontal and vertical spooling angles, allowing the client multiple options of where to site the reeler to for the deployment arrangement during operations. A large marine duty disc brake with fully adjustable braking force allows line pull value to be set so that the reel will slip to protect the safe working load of the umbilical. The design houses a 12-pass hydraulic slipring and multi-pass electric slipring to allow for live signals on all umbilical lines while the drum is rotating during deployment.

The Umbilical Arch Sheaves (SH-A-1028) were designed to match the minimum bend radius of the umbilical, with rollers machined to match outer diameter, both measures to prolong the lifespan of the umbilical. Spring loaded fixtures provide a quick release function for the umbilical and a hinge section on the lift point allows for the umbilical to loaded or removed while the sheave is suspended.

As a leading provider in the design, manufacture, refurbishment and rental of topside & subsea controls equipment, TIS have an extensive library of existing designs to offer or use as a base to develop a bespoke solution.

We have a comprehensive track record of delivering the highest quality control equipment on the market for Subsea Landing Strings, Well Access Systems, Lightweight Well Intervention Systems, IWOCS, Managed Pressure Drilling, and many more applications.

Bespoke HPUs can be engineered to govern multiple functions including pump control, subsea valve operation, ESD and EQD functions, all from a single containerised unit using a programmable logic controller system. Bespoke umbilical reelers can be configured to deploy and recover any length and diameter of umbilical product, with standard build types including SLS Umbilical Reelers, IWOCS Umbilicals, Drilling Umbilical Reelers, Lubricator Valve Umbilical Reelers, Nitrogen Hose Reelers and Cable Reelers.

Contact sales@tis-manufacturing.com to find out more about our bespoke engineering solutions for Topside Controls equipment.

As a leading provider in the design, manufacture, refurbishment and rental of topside & subsea controls equipment, TIS have an extensive library of existing designs to offer or use as a base to develop a bespoke solution.

We have a comprehensive track record of delivering the highest quality control equipment on the market for Subsea Landing Strings, Well Access Systems, Lightweight Well Intervention Systems, IWOCS, Managed Pressure Drilling, and many more applications.

Bespoke HPUs can be engineered to govern multiple functions including pump control, subsea valve operation, ESD and EQD functions, all from a single containerised unit using a programmable logic controller system. Bespoke umbilical reelers can be configured to deploy and recover any length and diameter of umbilical product, with standard build types including SLS Umbilical Reelers, IWOCS Umbilicals, Drilling Umbilical Reelers, Lubricator Valve Umbilical Reekers, Nitrogen Hose Reelers and Cable Reelers.