Since delivery, the equipment has seen a range of operations in Africa, Europe, Middle East and Southeast Asia, with the package comprised of the following:

Hydraulic Control Unit

Capillary Spooler Unit

Powered Sheave Injector Unit

Triplex Pumping Unit

Lightweight Slickline Unit

Lightweight Diesel Powerpack

Special Snubbing Head

TIS Capillary Systems are designed to deploy and recover capillary strings for well intervention by the delivery of chemicals to treat scale, paraffin, corrosion, salting, and other issues. All equipment in this package was built and certified in compliance with DNV-ST-E271 and CE ATEX Zone 2.

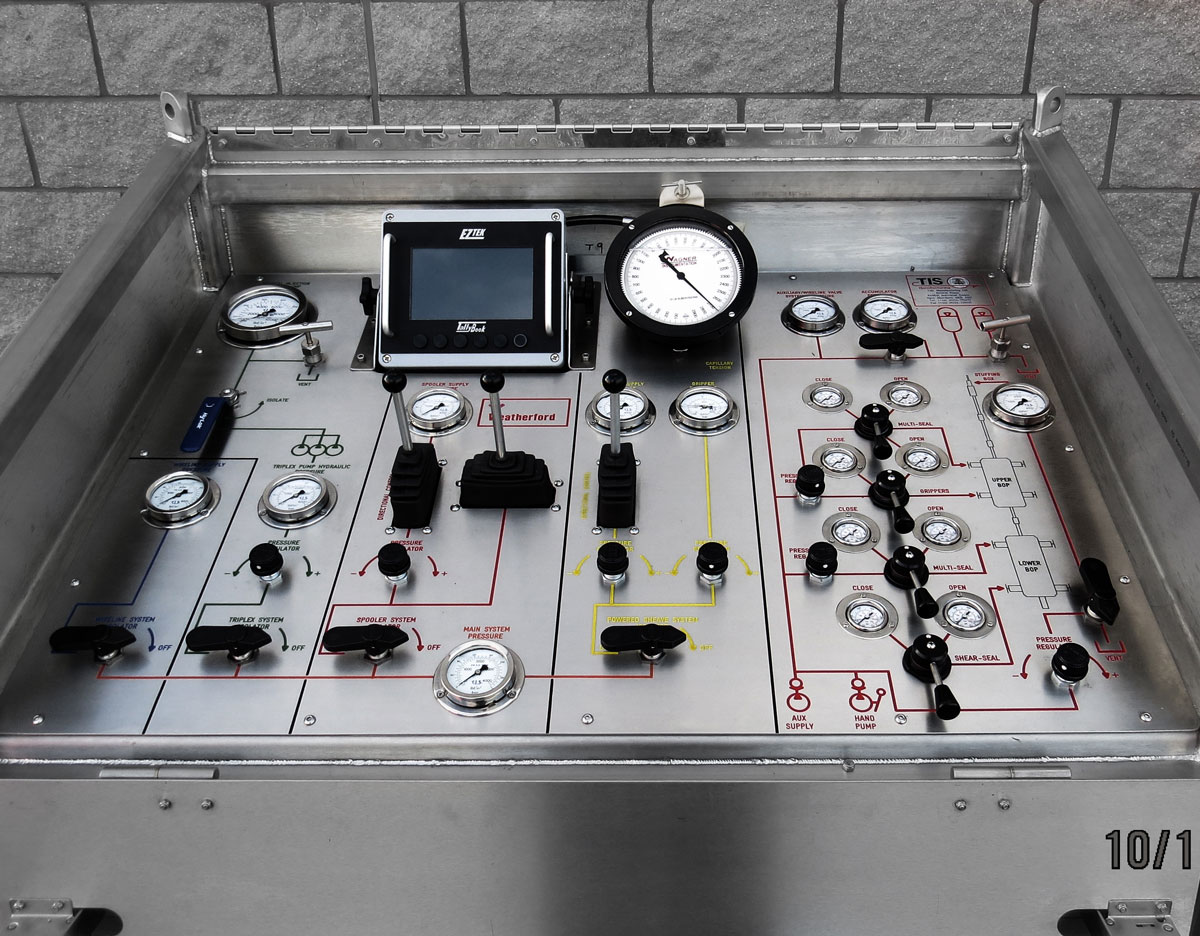

The Hydraulic Control Unit (CU-H-1001) is designed to provide control functionality for the Spooler Unit, Powered Sheave Injector Unit and 2x Dual Wireline Valves. The unit offers a portable control station which houses the required controls instrumentation fixed to a coloured engraved control panel.

The Capillary Spooler Unit (CS-A-1004) was designed to accommodate a range of drum diameters for deployment and recover of ¼” or 3/8” OD capillary. A level wind sub-assembly provides controlled spooling to the drum, a counter head measures the length as it spools, while counter balancing hydraulic system provides constant back tension against the accompanying powered sheave injector unit.

The Powered Sheave Injector Unit (PS-A-1001) was designed to provide controlled deployment and retrieval of ¼” or 3/8” OD capillary strings into the wellbore via the appropriate pressure control equipment. A carbon steel sheave wheel with two hardened surface grooves to accept the different sizes of capillary tube is driven via a direct mounted hydraulic motor.

The Triplex Pumping Unit (CU-P-2008) was designed for pumping various agents through the capillary string at 19L/min up to 6,000psi.

The Lightweight Slickline Unit (TW-A-2004-1) was designed to accommodate two separate drums of either 6,000ft of 0.160” wire or 20,000ft of 0.125” wire, for standard slickline intervention operations. The unit was supplied with a drum changeout kit to install drums in field, measuring head to for either size, and weighing less than 1,000kg when the drum is removed.

The Lightweight Diesel Powerpack (PM-A-2012) was to provide the necessary power required for the above equipment that makes up the lightweight capillary package. Critically, the powerpack was comprised of two separate skids for the engine and fluid reservoir, with each frame made of aluminium, providing two lifts weighing less than 1,000kgs each.